Home / Products / Filling Machines

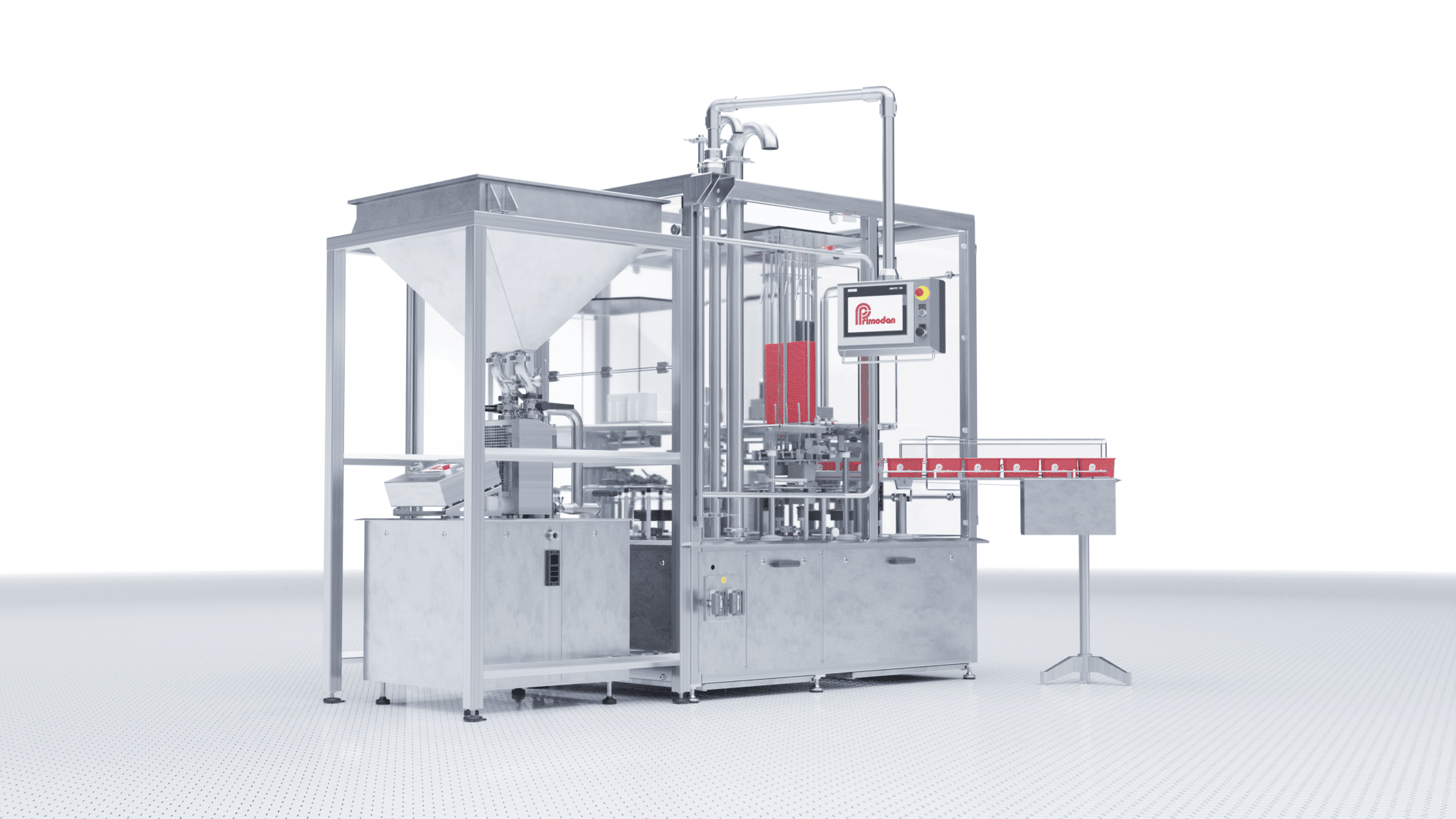

Filling Machines

Rotary vs. Linear

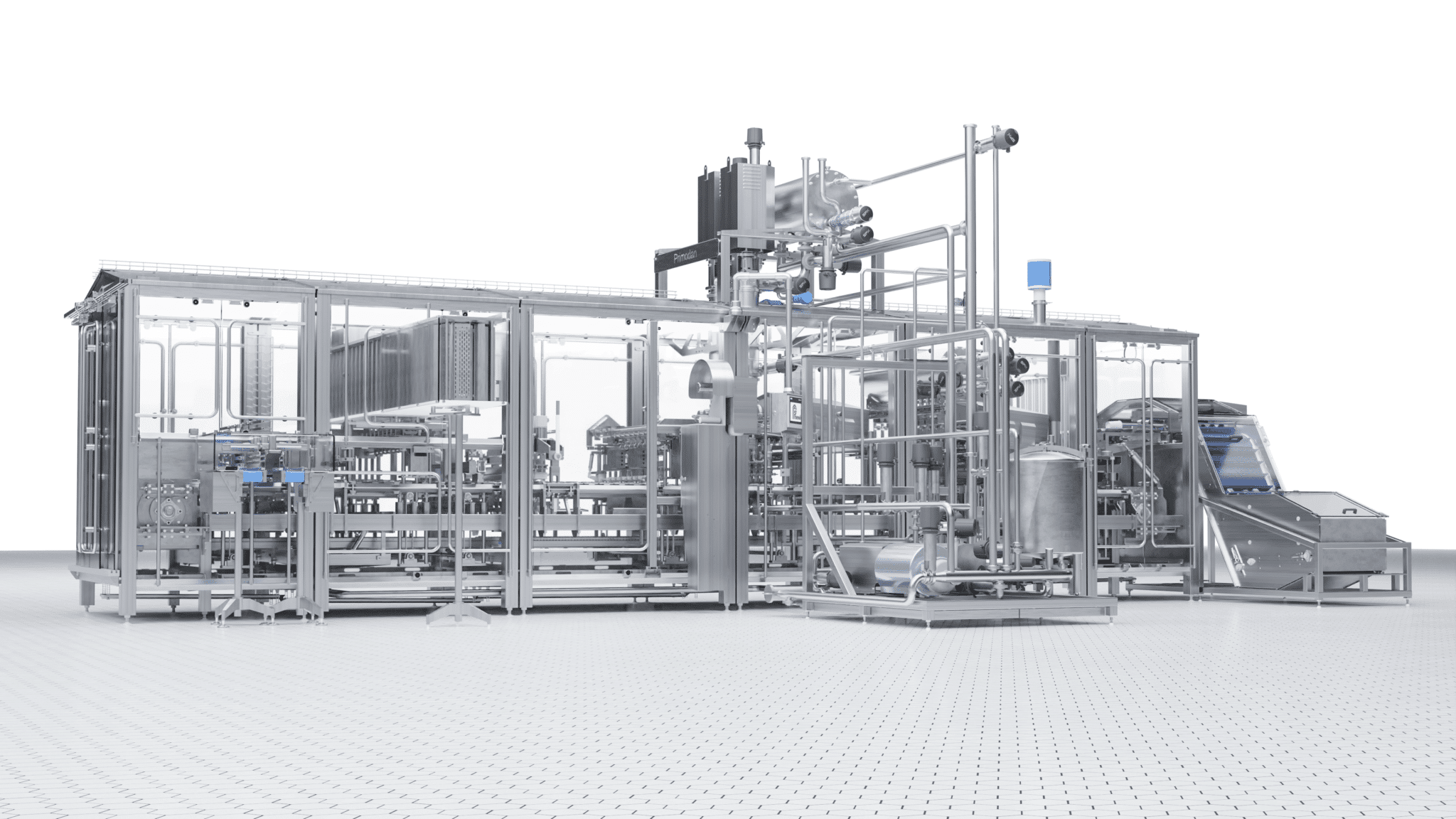

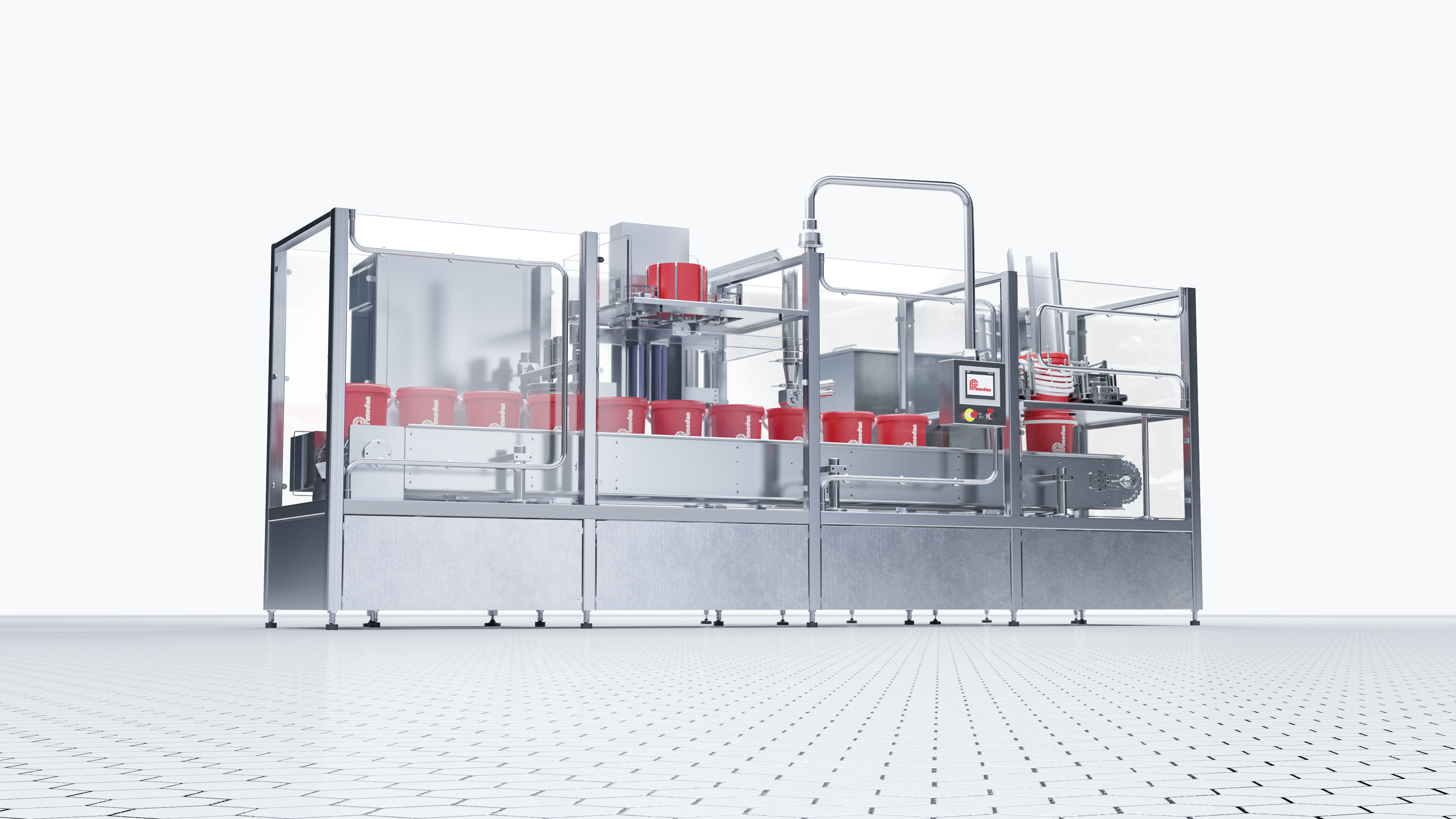

Primodan offers a wide range of filling machines for the food industry. Depending on capacities, formats and products we offer both rotary and linear types. For larger containers like buckets/pails up to 20 kg we normally go with linear solutions – we call them RT lines. For bottles and glass jars we offer linear as well as rotary options.

GUIDELINE for choosing either a rotary or linear cup filling solutions:

Criteria

Rotary Machines

Linear Machines

Best for

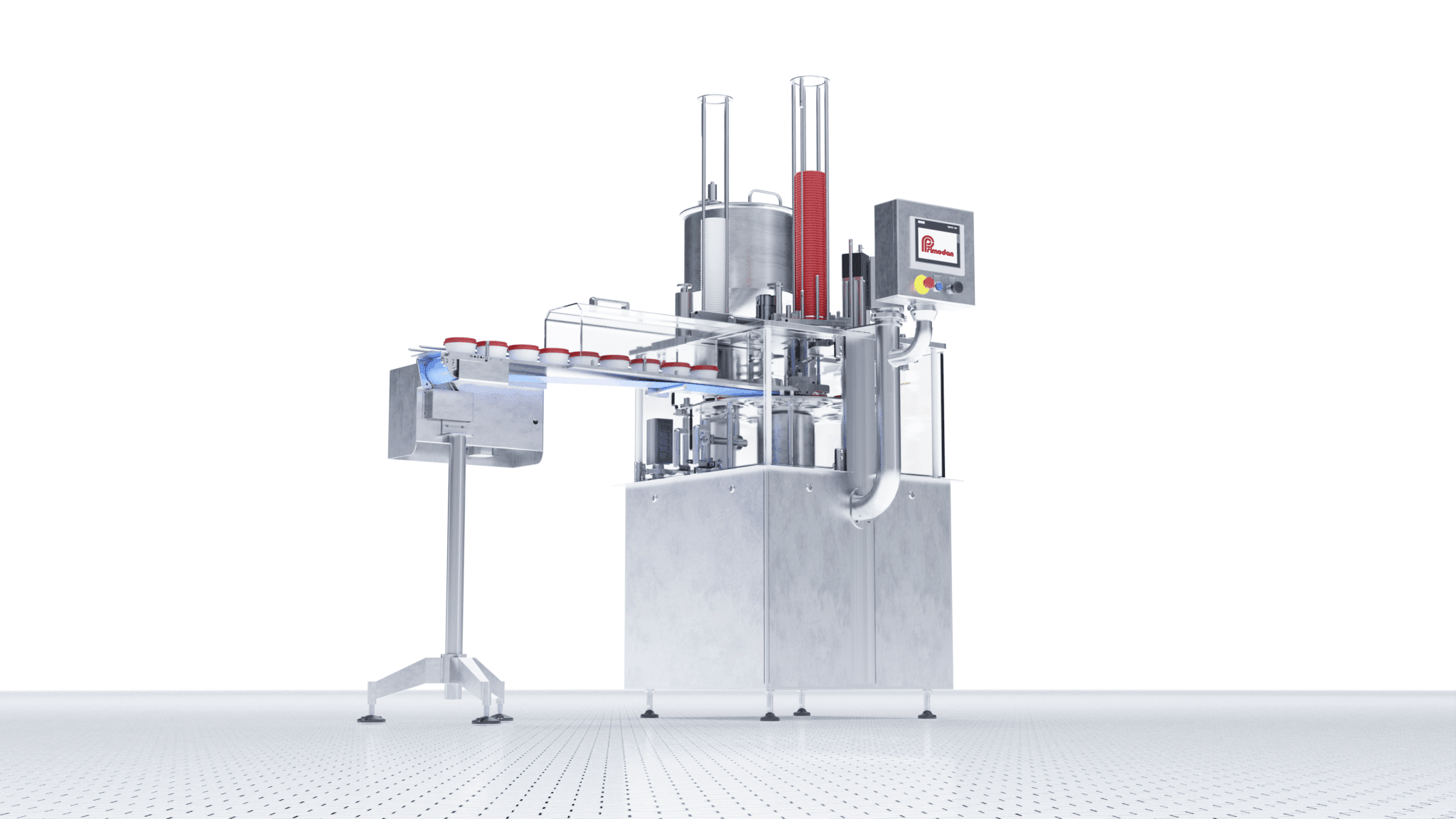

Low to medium volume, continuous production runs

Medium to large production runs with large batches

Capacity range

2.000-14.000 cups/hr

6.000-30.000 cups/hr

Footprint

Compact, space-saving

Requires more floor space

Changeovers

Very fast, often at the push of a button by full servo package – with different cup rim dimensions usually within 20 minutes

More time demanding – recommended max. 2 different cup sizes. Full servo package – height change-over from panel

Flexibility / Customization

Flexibility / Customiz- ation

From standard to Taylor-made – Adaptable to various packaging. Limitation 16 positions in roundtable

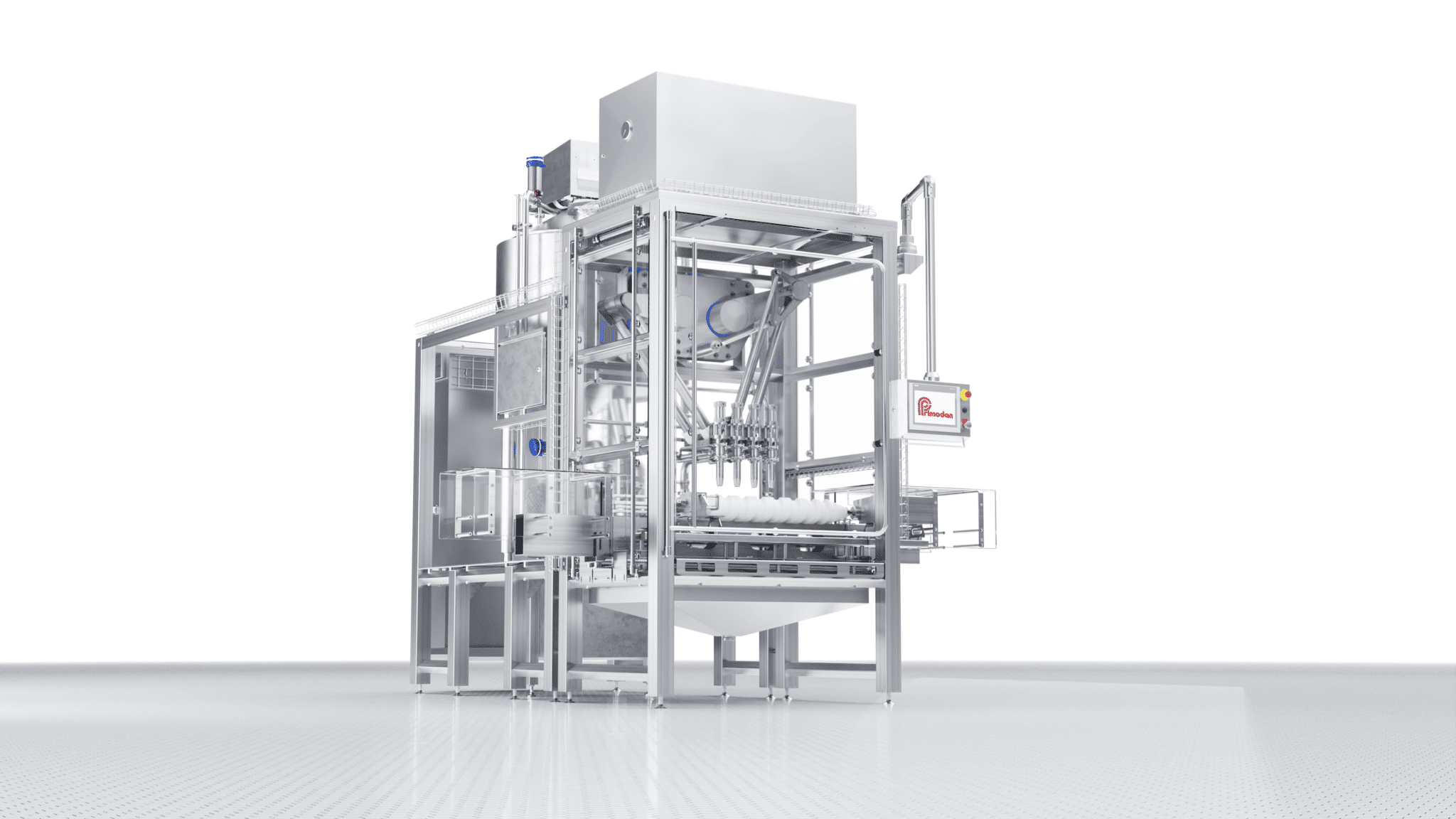

Highly customizable – Primodan’s unique modular design even allows adding features later. The linear design allows multiple filling stations and options.

Product Handling

Ideal for single or maximum 2 products into one package

Excellent for filling multiple products into one package

Precision & Accuracy

Maximum precision

Maximum precision

Complexity & Cost

Less complex, lower investment, lower TCO, lower cost for adding cup formats in the future

Higher complexity, higher TCO and larger footprint

When to Choose

If your priority is maximum flexibility between cup types and shapes and a reasonable output with many product changes

If you need many features/ operations, multi-product filling, and a high output with maximum 2 different cup rim dimensions

Hygiene matters

Primodan takes hygiene to the next level. Our solutions are designed to ensure maximum food safety and extended shelf life. We continuously monitor the market to implement the most efficient and cost-effective sterile technologies.